Neurocrine Biosciences

Neurocrine Aperture is constructing a 535,000 square-foot campus with aspirations to attract top talent in the life science industry. Neurocrine moved its headquarters to Carmel Valley to provide a convenient location for its employees. Since many life science companies have a location or headquarters in San Diego, Neurocrine wanted to get on board. In response, the organization signed the largest life science lease in the San Diego market.

A.O. Reed was awarded the plumbing and mechanical scopes on this cGMP project. As a design-assist partner, we provided valuable input when designing and installing the mechanical systems. There are six buildings total on campus.

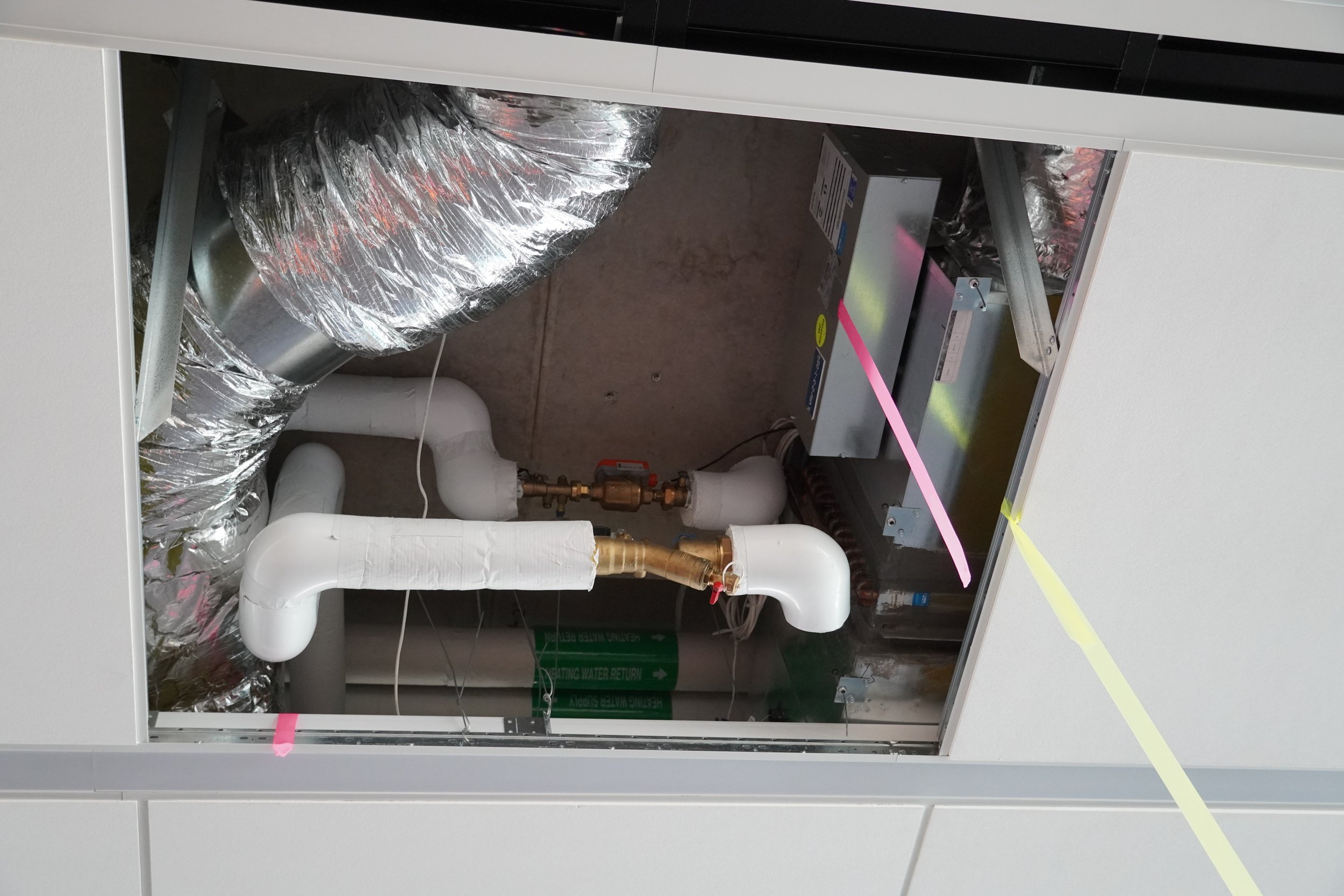

The mechanical scope for Neurocrine involves building a new 4,000-ton central plant with the capacity to expand to 5,000 tons. The central plant houses centrifugal chillers, pumps, and cooling towers to serve chilled water to the entire Neurocrine campus. The six buildings include a central plant, two office buildings, two laboratory buildings, and a fitness center. The two office buildings are served with roof-mounted custom air handling units located on the roof of each building. Each zone is served with a VAV reheat system and a plenum return system. The two laboratory buildings house research laboratories, cGMP facilities, and cleanrooms. The heating plant serves the entire campus and is located in the laboratory building. This consists of heating hot water boilers, steam boilers, and domestic hot water heaters. The mechanical system on the laboratory buildings includes custom roof-mounted VAV air handling units and strobic lab exhaust fans. The lab spaces are served with phoenix control supply and exhaust valves.

The plumbing scope includes roof, and overflow drains for each building, sanitary waste, laboratory waste systems, domestic and industrial cold and hot water, and natural gas piping. The specialty gases for the laboratories include compressed air, vacuum, CO2, oxygen, argon, nitrogen, liquid nitrogen, helium, and RO/DI system. The plumbing system also includes solvent systems and gases such as acetone, acetonitrile, ethyl acetate, methanol, and hexane.

This project will be constructed within 18 months. The project was complex, and A.O. Reed loves the challenge! We are able to show off our experienced team when providing valuable input during the design and installation process.