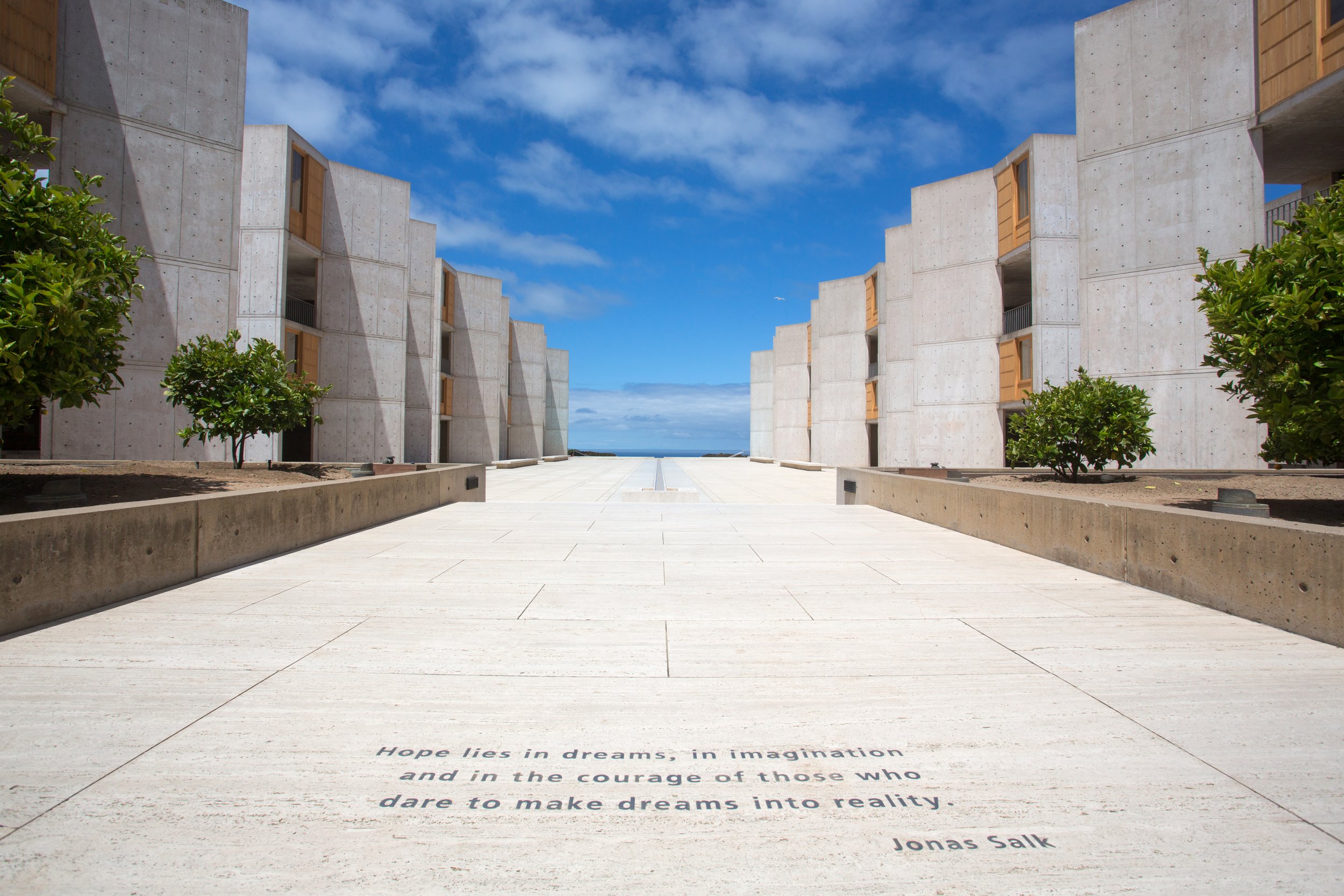

Salk Institute

A.O. Reed has been at the Salk Institute for the past fifteen years. We have participated in projects that vary in size and complexity on all four buildings on campus. From installing a one-million-dollar microscope to upgrading a central plant, there are remnants of A.O. Reed’s work throughout the campus.

One of our projects includes an air handling unit that was replaced in the upper mechanical space. This project was complex as the systems that were being replaced were old and in a consolidated room. We replaced all the piping and took out the old equipment in pieces. From there, we installed the new air handling unit in sections with the help of our sheet metal department. This supplies next door to a complex laboratory space. In the new lab, we installed fume hoods, autoclaves, lab sinks, and new controls for the heating system.

In 2010, we remodeled numerous mechanical and plumbing systems for the Salk Institute. Some equipment includes Seminole boilers and chillers. Next door to this space, A.O. Reed upgraded the central plant at the institute. We installed chillers and re-piped the systems. We designed and installed space for future valves of the chilled water system that will be utilized in the next expansion project. This was installed while maintaining operations at the institute. We underwent critical shutdowns and expanded our thinking to ensure all research assets weren’t compromised.

In the lower mechanical space, we have replaced heat exchangers. We have also replaced vacuum pumps that serve all vacuum in the lab benches. The compressed air systems have new compressors and purifications. During the remodel of the central plant, we re-piped all plumbing systems.

Since the Salk Institute is a large space with complex systems, engineers in the 1960s designed the building to have interstitial spaces between each floor during the original construction. These spaces allow room for storing mechanical and plumbing equipment to serve each laboratory underneath. These places hold air, gas, vacuum, cold water, DI fusion piping, glass piping, waste & vent systems, air conditioning, heating, chilled water, and heating hot water with futures. This allows an easy space to remodel the building.

The Salk Institute was built in 1963. Since then, this campus has undergone numerous replacement and expansion projects to ensure all scientists receive the most state-of-the-art systems. Nobel Peace Prize winners undergo research at the Salk Institute, so there is a critical need for the mechanical and plumbing equipment to deliver each and every time.